Empowering The depths

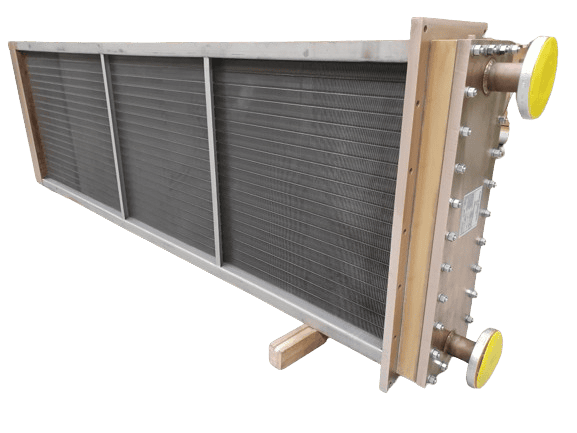

Cooling system marine engine

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Understanding marine engine cooling systems

Marine engines, much like their counterparts on land, require effective cooling to maintain performance and prevent overheating. The cooling system in a marine engine ensures that the engine operates within an optimal temperature range, crucial for durability and efficiency. Marine engines primarily use water from their surrounding environment—be it fresh or saltwater—to regulate temperature. This is achieved through a series of heat exchangers that transfer excess heat from the engine to the water, which is then expelled back into the ocean or lake. Essential components such as the heat exchanger, coolant, and the raw water pump play pivotal roles in this process. These systems are specifically designed to handle the corrosive nature of saltwater and the challenge of constant temperature fluctuations. Ensuring that these components are in peak condition is critical for the longevity and reliability of any marine propulsion system.

The vital role of heat exchangers in marine vessels

Marine engines face a unique set of challenges, primarily due to their operating environment—vast, open waters, often salt-laden and corrosive. The central component mitigating these challenges is the heat exchanger, a device critical to maintaining the engine’s longevity and efficiency. In marine applications, heat exchangers perform the dual function of cooling the engine’s internal combustion process and protecting it from the harsh marine elements.

How heat exchangers protect marine engines

The heat exchanger in a marine engine is akin to a guardian against the thermal and corrosive stresses that the engine endures. It operates by allowing seawater, which is often cooler than the engine, to absorb the excess heat without directly contacting sensitive engine components. This process involves a closed loop system where coolant circulates around the engine, absorbs heat, and then passes through the heat exchanger where it is cooled by seawater.

Closed loop vs. open loop systems

Marine engines typically utilize either closed cooling systems or open cooling systems. Closed systems circulate coolant in a sealed loop, only exposing it to seawater in the heat exchanger, thereby minimizing corrosion risk. Open systems, on the other hand, pump seawater directly through the engine, which, while effective in heat transfer, increases the risk of corrosion and scale buildup over time.

The challenge of corrosion and scale

Saltwater is particularly aggressive in terms of corrosion and scaling. Scale buildup can significantly impair the heat exchanger’s efficiency, leading to overheating and potential engine failure. Corrosion can degrade essential components, compromising the engine’s integrity and lifespan. Modern marine engines therefore often incorporate corrosion-resistant materials and coatings, and the heat exchangers are equipped with anodes that sacrifice themselves to protect more critical parts from galvanic corrosion.

Optimal temperature management

Maintaining an ideal temperature range is crucial for marine engine performance. Overheating can lead to engine failure, while excessively cool operating temperatures can increase wear and fuel consumption. Temperature control valves and monitoring systems are thus integral to modern marine engines, ensuring they operate within the safest and most efficient temperature ranges.

This delicate balance of heat transfer efficiency and corrosion resistance defines the performance and durability of marine engines. Innovations in heat exchanger design and materials continue to advance, pushing the boundaries of what marine engines can endure and achieve.

Download products reference list

Download the comprehensive product reference list for heat exchangers and cooling systems.

Dutch excellence in heat exchange

Customized solutions

With ICARUS Industrial, you're not just buying a product, you're engaging a partnership. Our direct sales model

Direct manufacturer benefits

Your unique needs are our command. We offer tailored heat exchanger solutions.

Lower total cost of ownership (TCO)

We go beyond performance with our heat exchangers, sculpting an unbeatable blend of.

Superior durability

Built from robust materials, our heat exchangers are a testament to resilience. They reduce maintenance

Elevate your marine engine's performance with ICARUS

At ICARUS, we understand the pivotal role that a high-quality cooling system plays in the performance and longevity of marine engines. Our finned tube heat exchangers are designed to meet the unique demands of marine environments, providing optimal heat transfer efficiency while combating the corrosive effects of seawater.

Why choose ICARUS heat exchangers?

Our products stand at the forefront of cooling technology, incorporating advanced materials and innovative designs that extend the service life of marine engines. Each heat exchanger is crafted with precision, ensuring that it not only meets but exceeds industry standards for durability and performance. With ICARUS, you gain peace of mind knowing that your marine engine is equipped to handle both the rigors of high seas and the challenges of temperature management.

Custom solutions and dedicated support

Understanding that each vessel has unique needs, ICARUS offers bespoke cooling solutions tailored to your specific requirements. Our team of experts is committed to providing unparalleled support, from initial consultation to ongoing maintenance. We assist you in selecting the ideal cooling system that aligns with your operational needs and environmental conditions.

Connect with Us Today

We invite you to explore how ICARUS can enhance the efficiency and reliability of your marine engines. Contact us today to discuss your cooling system needs and discover why ICARUS is the preferred choice for marine engine solutions worldwide. Experience the difference with ICARUS—where innovation meets the open sea.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers

Quotation Form

FACTS ABOUT ICARUS

> 27

With over 27 years in business, we’ve carved out a reputation for excellence and innovation.

> 120+

Our global presence is marked by a diverse clientele of over 120 customers worldwide.

> 850+

Moreover, our portfolio boasts more than 850 completed projects.

FAQ's about marine engine cooling systems

How does the exhaust system in marine engines affect overall engine performance?

The exhaust system in marine engines is crucial for maintaining optimal engine performance and efficiency. The exhaust manifold, exhaust elbow, and exhaust pipe work together to expel combustion gases from the engine block, ensuring that the engine runs smoothly and efficiently. Regular maintenance and inspection of these exhaust components help prevent damage and corrosion, which can impair engine function and lead to major damage.

What role does the water pump impeller play in marine cooling systems?

The water pump impeller is a key component in marine cooling systems, responsible for circulating raw water through the engine to regulate temperature. This cool water absorbs heat from the engine, preventing overheating and maintaining engine temperature within an optimal range. Regular inspection and replacement of the water pump impeller are essential for preventing overheating and ensuring the longevity of the marine diesel engine.

Why is the expansion tank important in a marine cooling system?

The expansion tank in a marine cooling system allows for the expansion and contraction of engine coolant as it heats and cools. This helps maintain the proper coolant level and pressure within the closed-loop cooling system. An expansion tank prevents overflow and potential damage to the engine, ensuring that the engine cools efficiently and operates at peak performance.

How does seawater temperature affect marine engines?

Seawater temperature has a significant impact on the efficiency of marine cooling systems. Cooler seawater enhances the heat transfer process in raw water-cooled engines, improving overall engine performance. Conversely, warmer seawater may reduce the cooling efficiency, leading to higher engine temperatures and potential overheating. Monitoring seawater temperature and ensuring that the cooling system is in optimal condition can prevent engine damage and maintain consistent temperature levels.

What is the difference between closed-loop and raw water cooling systems in marine engines?

Closed-loop cooling systems circulate coolant within a sealed loop, isolating it from seawater and reducing the risk of corrosion. Raw water cooling systems, on the other hand, pump seawater directly through the engine. While raw water systems provide effective cooling, they expose the engine to corrosive elements and require more frequent maintenance to prevent scale buildup and corrosion. Closed-loop systems are generally preferred for their durability and lower maintenance requirements.

Why is regular maintenance crucial for marine engines?

Regular maintenance is essential for ensuring the longevity and optimal performance of marine engines. Routine checks and servicing of components such as the heat exchanger, raw water pump, and hoses help prevent corrosion, scale buildup, and overheating. Keeping a maintenance log and following optimal maintenance tips can prevent irreversible damage, prolong the life of expensive components, and enhance the overall efficiency of the engine.

How do marine heat exchangers protect against corrosive scale?

Marine heat exchangers are designed to handle the harsh conditions of saltwater environments. They often feature materials like copper or copper/brass, which are resistant to corrosion. Heat exchangers also use anodes to combat galvanic corrosion, sacrificing the anode material to protect key components. This helps prevent corrosive scale buildup, maintaining efficient heat transfer and protecting the entire engine from damage.

What are the benefits of using ICARUS heat exchangers in marine engines?

ICARUS heat exchangers are designed with advanced materials and innovative designs to withstand the corrosive effects of seawater and ensure optimal performance. They enhance engine efficiency, reduce maintenance costs, and extend the service life of marine engines. ICARUS provides custom solutions tailored to specific operational needs, offering unparalleled support and expertise to boat owners and marine equipment operators.

How can boat owners ensure the health of exhaust elbows in their engines?

Boat owners can ensure the health of exhaust elbows by performing regular inspections and maintenance. Checking for signs of corrosion, wear, and blockage can prevent damage and maintain engine performance. Using high-quality marine coolant products and following manufacturer guidelines for maintenance can help keep exhaust elbows in optimal condition, preventing cold corrosion and other issues related to the exhaust system.

What steps can be taken to prevent water ingress in marine engines?

Preventing water ingress involves regular inspection of hoses, clamps, and seals to ensure they are in good condition and properly secured. Replacing damaged or worn-out parts promptly and using high-quality components can prevent water ingress. Additionally, boat owners should monitor the water level in the header tank and perform anode replacement as needed to protect against corrosion.